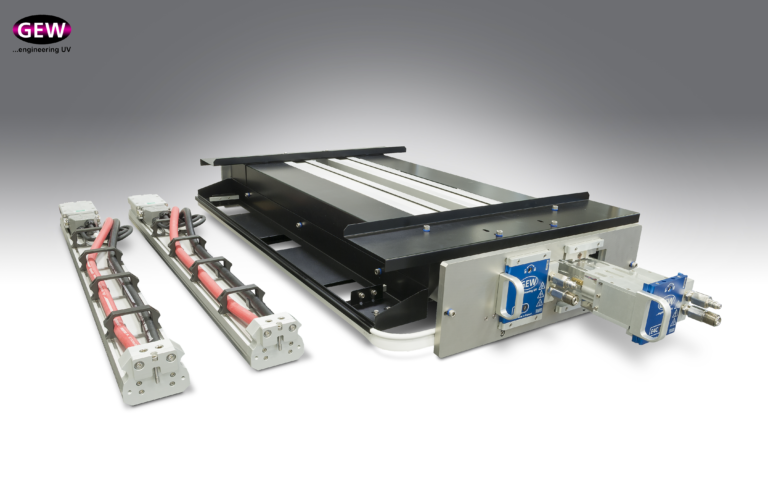

LED UV ประหยัดพลังงาน ที่มีประสิทธิภาพ เหมาะสำหรับงานพิมพ์ Commercial และ Packaging ไม่ว่าจะพิมพ์ลงบนกระดาษ พลาสติก หรือ กระดาษเคลือบฟอยล์

GEW LED UV สินค้าจากประเทศอังกฤษ

Previous

Next

https://www.youtube.com/watch?v=t8CdWB7yE4chttps://www.youtube.com/watch?v=gKUl11rdHCw&list=PLP3uaYE_36_35dh6eSf3lNrj1Unycs0mn&index=1

RMGT 920ST + GEW LED UV

Martin sums up his thoughts on LED UV and its future at Martin One Source: “For the environment it’s a better product… uses a lot less energy, I mean a lot less energy. Now with all the efficiencies, you know, and the economics of the LED UV we would never go back to the conventional UV… we will be LED UV users from here on out.”

RMGT 1050ST + GEW LED UV

On the question of the return on investment period for the LED UV system, Jordan comments: “With LED we do not need to use the IR dryers that we did need with conventional inks… because of that we’re saving money on electricity, with regard to not just the power output of the IR dryers versus the LED, but also the heat output – the IR dryers put out a lot more heat and because of that our air-conditioning in the summertime was huge – the bills were giant – now they’re much lower. I would venture to say they are a couple of thousand dollars a month cheaper. It’s not going to be very long before this system pays for itself.”

RYOBI 750G + GEW LED UV

J & J specialize in high end commercial work and offer the full range of processes to add value, including embossing, foil stamping, spot UV, soft touch lamination and perfect binding. They have a multitude of prestigious print industry awards to show for this work, and relish taking on ambitious and technically challenging projects. It is this willingness to push the boundaries that has led to J & J’s enviable reputation and their abundance of awards.

RYOBI 750G + GEW LED UV

KC have seen a steady rise in demand for uncoated work and LED UV has helped them greatly in this area, by enabling them to turn around uncoated jobs in the same time as coated or digital work. As Richard Coady, Operations Manager at KC says: “With LED UV we can print, finish and ship a heavy coverage bond job in the same day.”